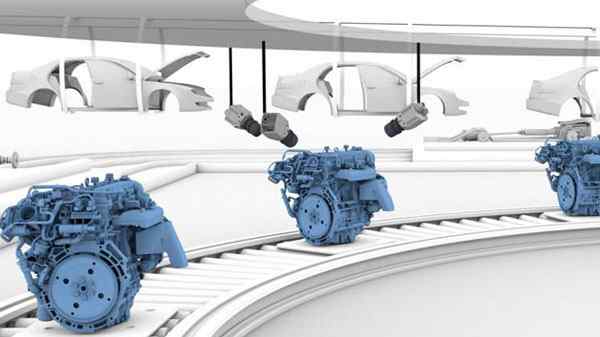

Vision Inspection for Product Traceability

Vision sensor is a powerful error proofing tool in manufacturing process. It provides reliable part position detection, dimension verification and accurate barcode reading.

Increases product quality

- Eliminates unreliable manual inspection

- Allows 100 % quality checking instead of audit checking

- Provides the resolution needed for reliable quality inspection

- Enables automated barcode reading

Increases productivity

- Improves line speed and error proofing

- Minimizes false code reads with very high code resolution

- Catches errors sooner to reduce unplanned downtime

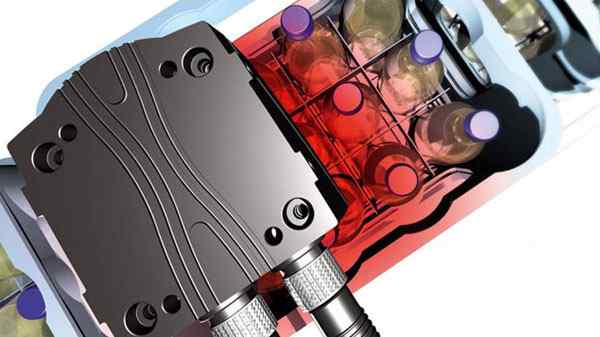

The vision solutions BVS meet the growing demands of state-of-the art production systems for high productivity, flexibility, and maximum quality. The vision sensors BVS E offers a large number of extremely efficient image processing functions. These functions can be flexibly combined for reliable fault detection and quality inspection, or for the secure reading and verification of codes. The vision sensor BVS E proves its reliability time after time.

Advantages of the vision sensor BVS E

- A vision sensor replaces many different sensors

- Flexible configuration

- Easy to use; PC software for all sensor types

- Robust and industrial-grade

- Easy and flexible installation

- Low costs and fast ROI

Featured Products:

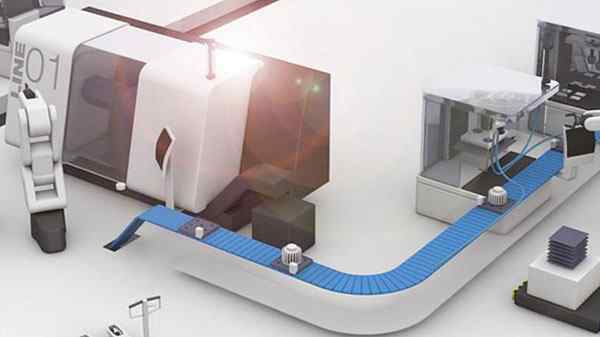

SmartCamera for machine vision

- Smart data management for limiting the load on Profinet

- Simple integration into the production environment through IO-Link

- Safe, customer-specific result management for the controller or for the server

- Robust, industrial-grade design