Experience the Future of Factory Logistics with Autonomous Delivery Robots

Intelligent handling enables seamless connectivity and rapid response at every stage of production planning, playing an irreplaceable role in intelligent manufacturing.

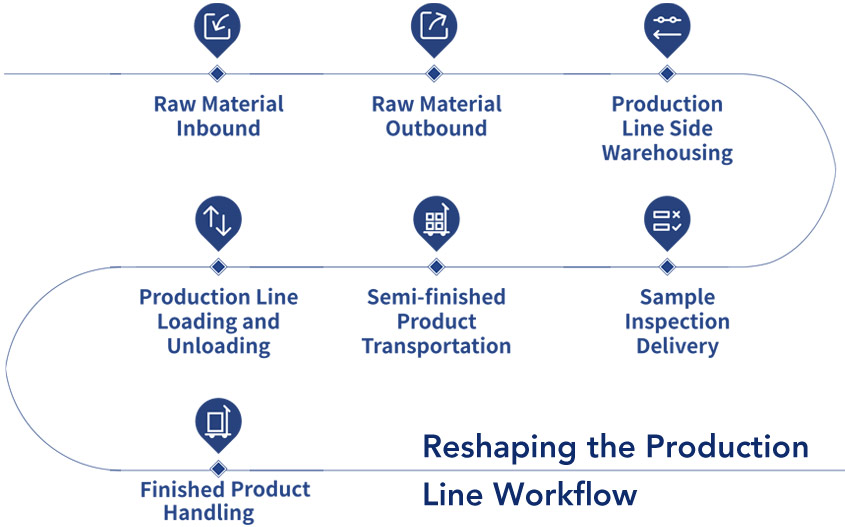

Usage Scenarios of Industrial Delivery Robots

Benefits of Industrial Smart Delivery Robots

Intelligent handling enables seamless connectivity and rapid response at every stage of production planning, playing an irreplaceable role in intelligent manufacturing.

Production Line based Smart Matching

- JIT matching line

- Lean production

- Production order and distribution information

High Efficiency

- 24*7 operation

- Fast delivery speed

- Replacement of repetitive manual work

- Full record of material and delivery tasks

Digitalized Management and Control

- Flexible task setting

- Timely delivery

- Fixed route loop delivery

- Traceable operation logs

Flexible Material Delivery Structure

- Rapid switching of large quantities of materials during production changeovers

- Flexible scheduling and allocation

Time and Manpower Savings

- Cost savings

- Release from laborintensive work

- Remote monitoring and robot tasks scheduling

Enhanced Brand and Competitiveness

- Smart production system

- Enhanced production competitiveness

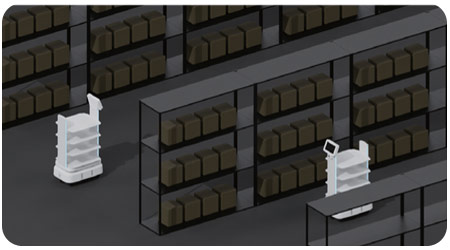

Lifting Robots

Intelligent Lifting robots have lifting functions, can autonomously identify shelves, and perform lifting operations, achieving unmanned material handling. Production System Integration: Supports quick integration with MES, ERP, WMS systems, and supports production system task assignment to robots.

Flexible Customization and Expansion

Maximum Load Capacity: 150kg

Dimension: 740×500×1240mm

Maximum Load Capacity: 300kg

Dimension: 740×500×1240mm

Maximum Load Capacity: 300kg

Dimension: 900×600×1240mm

Maximum Load Capacity: 600kg

Dimension: 950×650×1240mm

Factory Delivery Robots

Standard model for light item handling, agile movement, intelligent operation in narrow spaces such as production lines, reducing ineffective personnel movement and improving efficiency. Extended chassis with a load capacity of up to 300kg, supporting flexible customization and replacement of carriers.

Flexible Customization and Expansion

Maximum Load Capacity: 80kg

Dimension: 570×500×1240mm

Maximum Load Capacity: 150kg

Dimension:740×500×1240mm

Maximum Load Capacity: 300kg

Dimension: 740×500×1240mm

Maximum Load Capacity: 300kg

Dimension: 900×600×1240mm

Advantages of Industrial Robots

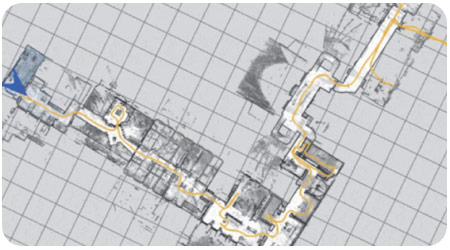

Rapid Deployment in Minutes, Simple and Convenient

- Fully Remote Deployment

- Zero On-site Presence Required

- No Limitation on Site Size

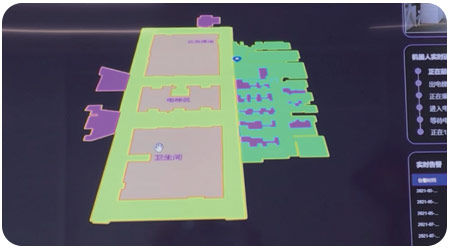

Stable Positioning, Navigation, and Obstacle Avoidance in Complex Factory Environments

- Multi-sensor Fusion Technology Based on AI Deep Learning Algorithms

- Multi-level Navigation Routing

- Sensible Obstacle Avoidance in Three-dimensional Space

Open at the Source Code Level, Quick Integration with Factory Systems

- Open API/SDK at the Chassis Level

- Compatible with WMS, MES, RCS Systems

- Modular Openness at the Algorithm Level for Software and Hardware

Flexible Customization for Factory Material Handling

- Flexible Adjustment of Workflow Settings

- Routes and Material Handling Processes Easily Adjustable

- Intelligent Autonomous Charging Strategy

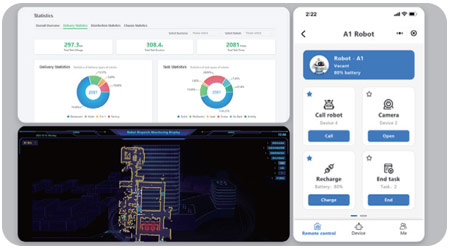

Multi-robot Intelligent Scheduling

- Local + Cloud-based Scheduling

Compatible with Indoor and Outdoor Environments

- Seamless Navigation in Complex Indoor and Outdoor Conditions

Multi-terminal + Cloud Integration Solution

- Robots can be Operated via Robot Terminals, Mobile Phones, PADs, PCs, etc.

Robot Big Data Cloud Computing Platform (Support Private Cloud, Offline Operation)

- Flexible Over-the-Air (OTA) Upgrades for the Entire Robot

- Real-time Remote Monitoring via Cloud