Selecting Industrial Panel PC for Food Industry

Safety, Hygiene, and Reliability

In the food and beverage processing industries, hygiene is of the utmost importance, from meat processing, to filling and packaging goods, all environments in the production facility have to be spotless and contamination free.

The whole production facility has to be thoroughly cleaned every day, with extensive wash downs with cleaning agents and high pressure, high temperature sprays to ensure disinfection of the food processing areas.

Stainless Panel PC has to be able to handle the hazards in the food processing environments where dust, dirt and liquids have to be cleaned off all machines in the facility daily to prevent food contamination.

Features:

Corrosion-resistant stainless steel housing

Corrosion-resistant stainless steel housing

Industrial Panel PCs and HMI installed in a food processing or chemical factory floor are often wet, dusty, and repeatedly cleaned with aggressive chemicals that can easily cause corrosion. That is why SUS 316 / AISI 316 stainless steel material is the first choice when it comes to product design.

The housing made of resistant to corrosive environments SUS 316/ AISI 316 grade stainless steel.

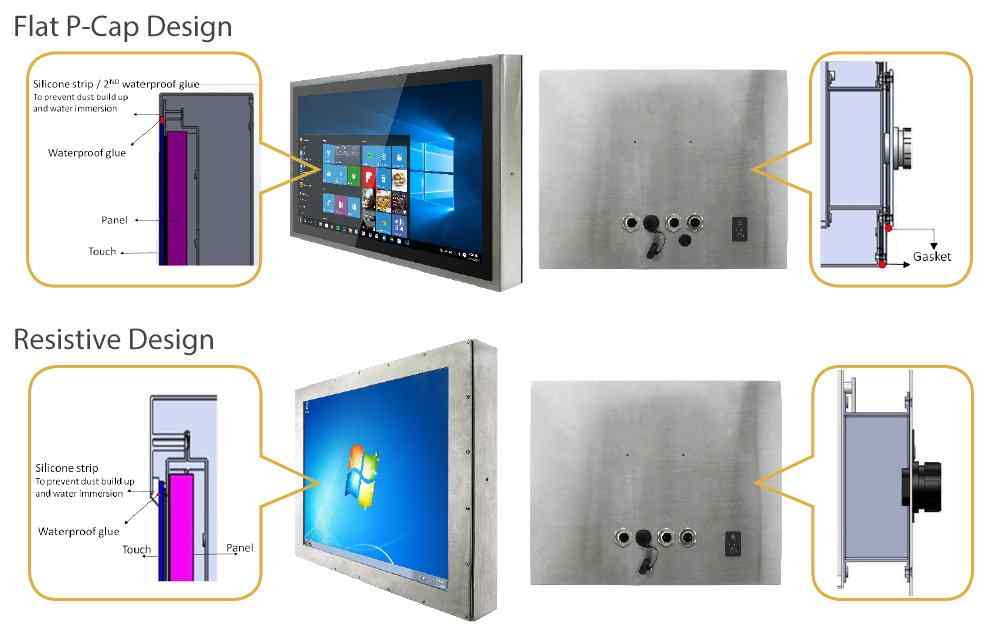

Water and dust protection IP69K / IP67 / IP65

Water and dust protection IP69K / IP67 / IP65

The IP Code, International Protection Marking, IEC standard 60529, sometimes interpreted as Ingress Protection Marking, classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water.

Ingress Protection (IP) rating notifies that the unit is water and dust-resistant. For example, the IP65 level indicates that the device's enclosure has no ingress of dust, complete protection against contact (dust-tight), and is protected from water jets.

Operational Safety & Operator user-friendly interface

The included air vent valve comes with an automatic mechanical system to act as a safety feature that controls and maintains pressure without manual assistance to avoid air-related problems.

Responsive touchscreen guarantee user-friendly experience for operators even when wearing gloves.

Broad Industrial Applications:

| IP65 Stainless Panel PC with Push Buttons

When an emergency occurs, we don’t want to waste time navigating through HMI screens but a simple and quick way to shut down the process. In terms of machine integration, push-button devices are easy to install and wire and straightforward for understanding the function and use. The wiring time is saved by over 60%, and the installation cost is reduced by more than 30%. |

| IP65 sleek round corners Stainless Panel PC

Its stainless steel housing and fanless design with IP65 protection make it suitable for frequent wash down operations. Experience intuitive and user friendly touchscreen panel, even with gloves or wet uses. |

| IP67 Resistive Panel PC

Also, there are plenty of I/Os, including USB 2.0, RS232 serial port, and RJ45-10/100/1000 LAN ports. Our signature rugged design can be seen in the Panel PC’s scratch-resistant touchscreen for added resilience. |

| IP69K Stainless Panel PC

M12 connectors, fanless cooling system and ultra-low power consumption, and various connectivity options are designed with industrial applications in mind. The panel PC has plenty of I/O ports, including USB 2.0, RS232, and RJ45-10/100/1000 LAN, to guarantee connectivity and compatibility.

|

| IP69K Stainless Panel PC with a waterproof conduit pipe

The IP69K rating makes these Panel PCs suitable for substantial wash downs, while the stainless housing with strong cleaning agents and perfect for food and chemical industries. Plus, the panel PC is easy to set up with either VESA or Yoke mounting options. Experience intuitive user controls with projected capacitive Multi-Touchscreen - zooming, tapping, scrolling, and more gestures. |

Water and Dust Protection

The IP Code, International Protection Marking, IEC 60529 (EN 60529), also known as Ingress Protection (IP) rating, classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water. The 1st digit indicates the level of protection that the enclosure provides against access to hazardous parts (e.g., electrical conductors, moving parts) and the ingress of solid foreign objects. The second digit indicates the level of protection that the enclosure provides against harmful ingress of water.

However, the highest does not mean the best. The choice depends on your application requirements and the environment where you are going to deploy the HMI solution. Generally speaking, for food and beverages industry there are four possible protection levels: IP69K, the highest, IP67, IP66 and IP65.