Machine vision

Smart Vision products - BVS VisionSensor meet the increasing demands for maximum quality and great flexibility in modern manufacturing plants through integrated industrial image processing.

Digital industrial cameras with USB and Ethernet interfaces have an analog/digital converter, which makes a frame grabber superfluous and significantly simplifies handling.

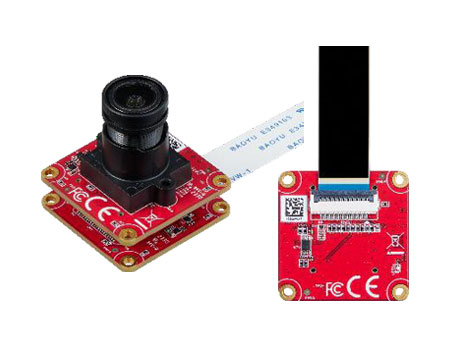

MIPI camera modules optimize image quality for different AI applications depending on the needs of customers, in order to meet the demand for high-speed and high-resolution applications in different embedded systems.