AD-WISE-2410

LoRaWAN Wireless Vibration Sensor. 3-axis accelerometer

- LoRaWAN wireless connectivity

- Built-in 3-axis accelerometer and temperature sensor

- Computing total 8 vibration characteristic values on board

- Compliant with ISO 10816

- IP66 with battery-powered, no wiring installation needed

- Easy setting with user friendly interfaces on WISE Studio

- Support wide temperature -20 ~ 85 °C

- RED Compliance

Smart Vibration Sensor

Battery-Powered

Utilizing LPWAN technology means that the WISE-2410 series can be powered by 3.6-V AA lithium battery.

Easy Operation with WISE Studio

With WISE Studio, you can set up operation parameters for frequency, report intervals, and alarms and more.

3-axis Vibration Inspection

WISE-2410 series uses 3-axis composite measurements to detect vibration and transfers those characteristic values

Explosion Proof

WISE-2410X is CID2, ATEX and IECEx (Zone 2 and Zone 21) certified for installation in hazardous and explosive environments.

Predictive Maintenance Solution

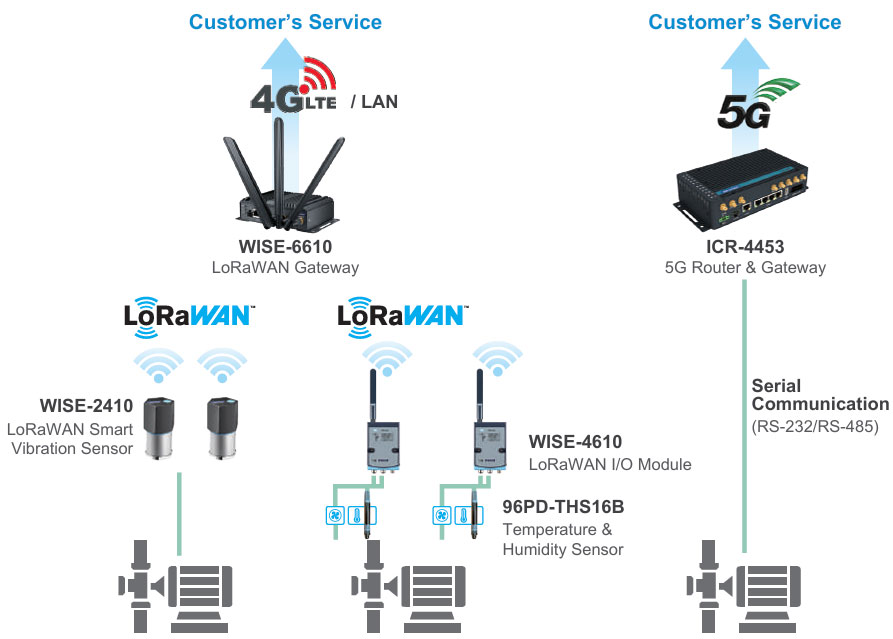

Vibration sensor and PT1000 temperature sensor both play key roles in predictive maintenance as it can monitor machine health and detect problems before unplanned down times occur. By utilizing LoRaWAN, this turnkey predictive maintenance solution provides long-range bidirectional communication between sensors and gateways.

WISE-2410 & WISE-2410X

LoRaWAN Smart Vibration Sensor

The WISE-2410 series is a LoRaWAN wireless condition monitoring sensor featuring an ARM Cortex-M4 processor, LoRa transceiver, 3-axis accelerometer, and temperature sensor. The WISE-2410X offers the same features with added explosion-proof capabilities.

- LoRa LPWAN with 5-km line-of-sight communication

- Superior penetration, low interference

- Easy to organize LoRa network data access

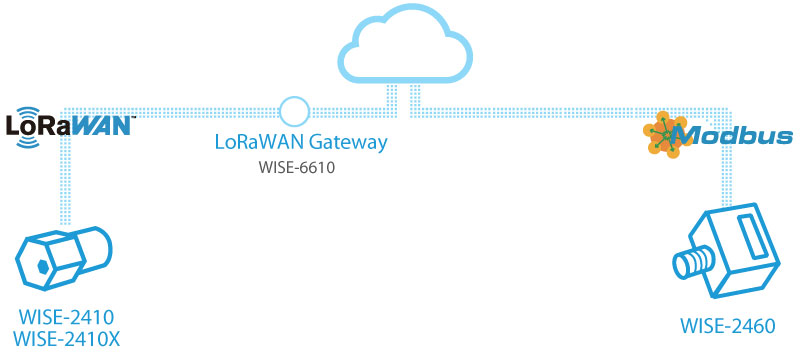

WISE-2460

Smart Vibration Sensors

WISE-2460 is a robust RS-485 smart vibration sensor integrated with an ARM Cortex-M7 processor, 10KHz@1- axis high detection range accelerometer and temperature sensor. This powerful computing device balances the bandwidth between edge devices and the application service on the user side.

- RS-485 serial communication through Modbus/RTU protocols

- 10KHz@1-axis frequency detection range

- Support max 10 customize detection ranges between 5 ~ 10,000Hz

LoRaWAN solutions

LoRaWAN solutions provide a device-to-cloud solution by simply sending collected data through the LoRa gateway to the cloud. With Edgelink inside the gateway, users simply plug-and-play without worrying about data parsing processes.

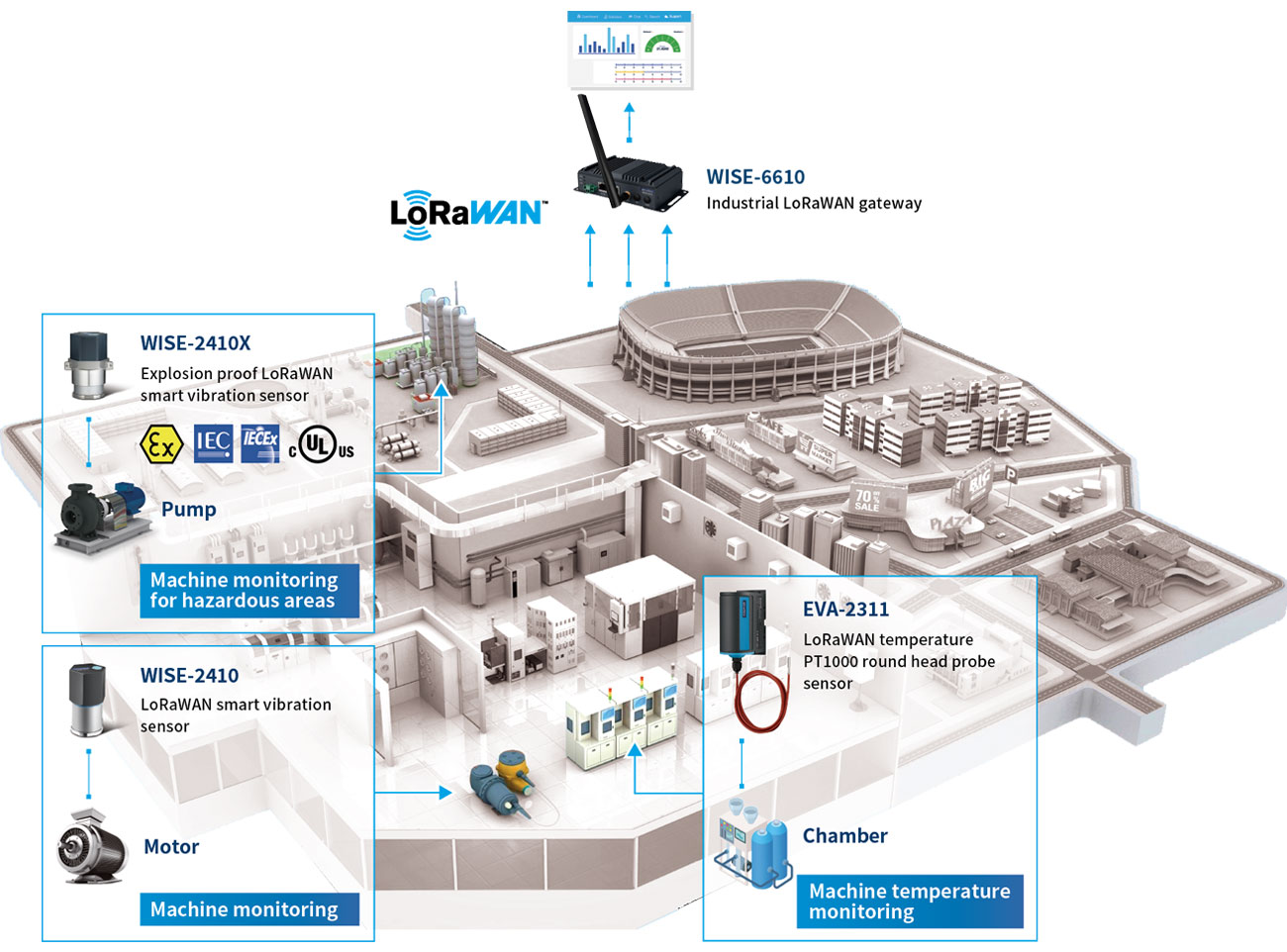

Factory Industrial IoT

In Factory Industrial IoT, the core objective is deploying diverse sensors to gather extensive data for analysis at a control center. Users set system thresholds and receive timely alerts for safety and productivity.

The WISE-4610 LoRa/LoRaWAN I/O node, along with WISE-2410 vibration sensors, ensures strong signal penetration without complex wiring. Integrating the EVA-2311 LoRaWAN Temperature PT1000 Round Head Probe Sensor enhances this network. Together, they monitor warehouses using vibration, humidity, and temperature sensors, providing an efficient alternative to manual inspections.

With WISE-2410 vibration sensor, EVA-2000 PT1000 sensor, and other sensors paired with a WISE-4610 analog input I/O board, alerts can be triggered when pressure levels (water pressure, oil pressure, gas pressures etc.) are abnormal. This increases safety and improves production quality by controlling resources in the manufacturing process.

Smart Agriculture

LoRaWAN solution used in smart agriculture connects WISE-2410 vibration sensor, EVA-2310 temperature and humidity sensor, and other sensors with the WISE-4610 outdoor LoRa/LoRaWAN I/O node. Together they send data through a WISE-610 LoRaWAN gateway to the cloud. In this case, the application collects temperature, humidity, vibration and soil PH data to better understand the environmental situation.

WISE-4610 is designed with an IP65 enclosure and M12 connectors to offer an optimal fit for outdoor applications. WISE-2410 is a LoRaWAN wireless vibration sensor integrated with ARM Cortex-M4 Processor, LoRa transceiver, 3-axis accelerometer and temperature sensor. EVA-2310 comes with a temperature detection range of 20 °C to 55 °C and a humidity detection range of 0%RH to 100%RH.

The WISE-6610 is a high-performance LoRaWAN gateway with reliable connectivity options for industrial environments and LoRaWAN protocol support for building LoRaWAN private and public networks.

Oil & Gas

Oil refineries are very large industrial complexes that involve many different processing units and auxiliary facilities. These facilities are dispersed over a vast industrial complex, and some of them are in hazardous environments or nearly inaccessible locations, making maintenance extremely difficult.

The WISE-2410X, an ATEX2 and IECEx (Zone 2 and Zone 21) certified vibration and temperature sensor, can be installed in hazardous environments to monitor the conditions of rotating equipment like fans and pumps. By integrating with Actility’s ThingPark Enterprise IoT platform and AWS IoT SiteWise,

LoRaWAN vibration sensing device can automatically and remotely monitor systems, making them a perfect facility monitoring solution for refining systems.

Energy Management

LoRaWAN solution enables smart campus energy management, which collects energy data and monitors power consumption in real-time. The LoRaWAN technology not only provides long-range wireless communication but also provides deep indoor coverage to easily cover multi-floor buildings.

Advantech builds the LoRaWAN network with its EVA-2210 3-phase current meter with 3 x 75A clamp-on CT, WISE-2200-M I/O modules and WISE-6610 LoRaWAN gateways to transmit the data from power meters to the cloud. EVA-2210 measures diverse equipment currents like pumps, compressors,

and more. WISE-2200-M is a LoRaWAN Modbus read/write communication device, which supports a maximum 128 addresses and a 30 rule setting and can easily connect to Modbus sensors and meters for different kinds of applications. Because of its plug-and-play functionality, EVA-2210 and WISE-2200-M can be quickly and flexibly installed to facilitate network construction.

Case Study: Smart Condition-based Monitoring (CbM) Solution in Compressed/Clean Dry Air (CDA) System

Background

In a competitive semiconductor industry, where high volume and maximum efficiency mean everything, a high reliable wireless technology used in remote facility monitoring application may be a suitable processing aid.

Compressed/clean dry air (CDA) is employed in fabs to drive pneumatic components of manufacturing process equipment, control valve functioning, or clean materials/ equipment. To smooth the manufacturing processes, CDA system must to be monitored by facility maintenance department.

System Requirements

Customer required a plug and play, remote facility monitoring, controlling and inspection wireless solution. To achieve this goal, we provide Advantech LoRaWAN solution. In this solution, we provide WISE-2410, vibration sensor, for compressor inspection and WISE-4610 with its’ WISE-S617 flexible I/O for environment and facility current power monitoring

System Description

WISE-6610 is a LoRaWAN gateway which supports Modbus TCP protocol can connect to any SCADA system in the world. WISE-2410 offers an easy way for rotating facility inspection application by following ISO-10816 standard. Moreover, WISE-2410 also supports 3-axis vibration detection and with IP66 rating, wide temperature design can conquer harsh environment where compressor located.

WISE-4610 with its’ WISE-S617 flexible I/O solution fulfill different kinds of remote facility monitoring and controlling application. It has DO for switch control and has AI/DI/RS-485 channels for sensor and plc connection.