Industrial Lifting Robot

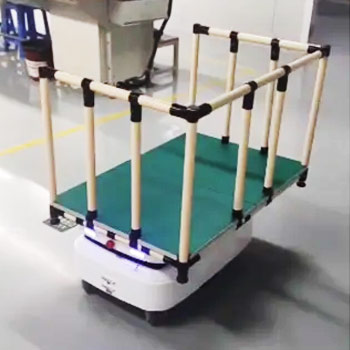

The lifting robot excels in operations within confined spaces while possessing lifting capabilities to handle various heavy goods. This design positions it for extensive applications in warehousing logistics, significantly enhancing efficiency and flexibility.

Shelves Lifting Robot - Up to 600kg Payload

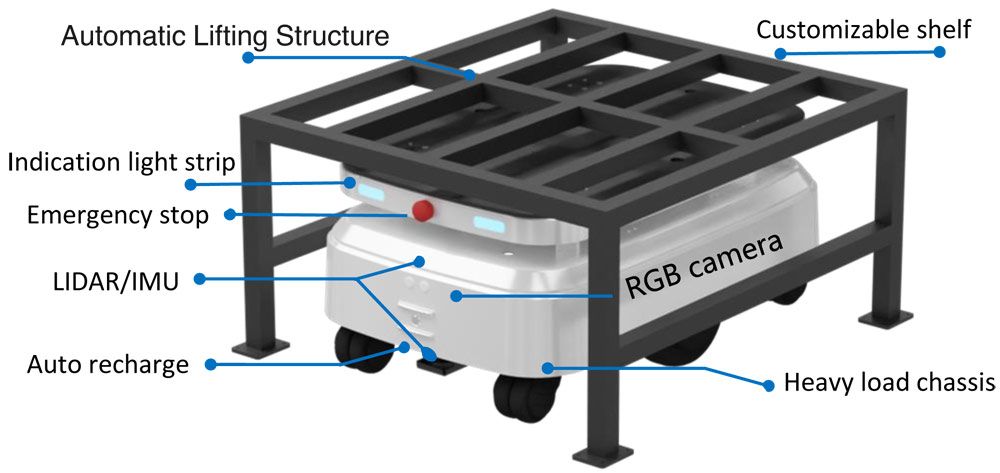

The lifting robot adapts to various types and sizes of shelves, enabling rapid deployment. Employing advanced multi-sensor fusion technology, it accurately identifies the surrounding environment, navigates obstacles with ease, and efficiently handles goods, elevating the intelligence of warehousing management.

The robot have lifting functions can autonomously identify shelves, and perform lifting operations, achieving unmanned material handling. This technology significantly reduces human operational errors, enhancing the accuracy and reliability of warehousing logistics.

Shelf-Lifting Robots

Intelligent Lifting robots have lifting functions, can autonomously identify shelves, and perform lifting operations, achieving unmanned material handling. Production System Integration: Supports quick integration with MES, ERP, WMS systems, and supports production system task assignment to robots.

Flexible Customization and Expansion

Maximum Load Capacity: 150kg

Dimension: 740×500×310mm

Maximum Load Capacity: 300kg

Dimension: 740×500×310mm

Maximum Load Capacity: 300kg

Dimension: 900×600×310mm

Maximum Load Capacity: 600kg

Dimension: 950×650×365mm

The 600kg heavy-payload industrial robots redefine the boundaries of industrial transport with their exceptional load capacity, high intelligence, and seamlessly integrated ecosystem, offering robust support for enterprises seeking automation and intelligent upgrades. The unique lifting function enables these robots to autonomously identify shelves and precisely perform lifting and placing operations. This facilitates end-to-end unmanned material handling from storage to production lines, significantly reducing labor costs while enhancing operational precision and safety.

Multiple Operation Modes, Simple Interaction

Robot Call Pager

Remote call robot and multi-point delivery

IoT Devices Integration

Seamless navigation through elevator, gate and automatic door handling

Follow Device

Robot can recognize and follow people

Lifting Robot Applications

Lifting robot automates the transfer of semi-finished products between factory production lines. Simultaneously, they facilitate intelligent communication between production lines, injecting a greater level of intelligence and efficiency into the manufacturing process. This technology not only enhances material handling efficiency but also alleviates the strain on human resources, infusing innovation and vitality into industrial transformation.