Overall Equipment Effectiveness Solution

Overall Equipment Effectiveness (OEE) solution realizes industry 4.0 through data acquisition, and analysis of machine availability. OEE improves productivity, reduce loss, and increase profit.

Overall Equipment Effectiveness (OEE) Solution combines hardware and software into integrated industrial applications, manufacturers can adopt a step-wise approach to realizing their intelligent factory. OEE solution provides a cost-effective approach to expediting project development with value-added applications that meet the criteria of Industry 4.0.

Three Steps to Start Your Industry 4.0 Journey with OEE SRP

Data Acquisition

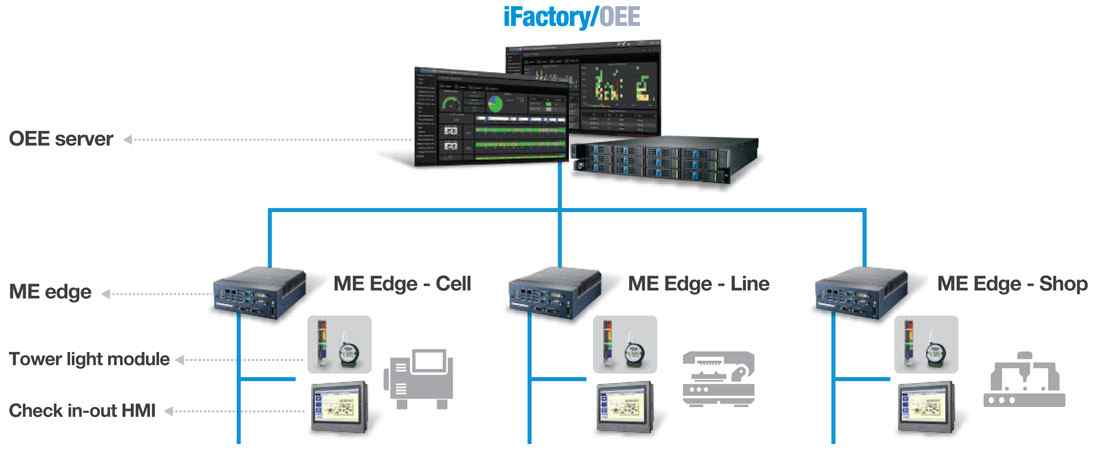

With WISE-PaaS/EdgeLink edge data acquisition software, data collected from different machines and multiple facilities goes through the OEE edge into one single platform.

Data Computing & Visualization

With WebAccess/SCADA software, data is aggregated in the OEE server or WISE-PaaS cloud platform. Data is analyzed and visualized as dynamic information assets with the iFactory/OEE application.

Central Management

Contextualized and visualized OEE data both real-time and historical enables managers to gain significant intelligence and actionable insights for optimizing operational efficiency.

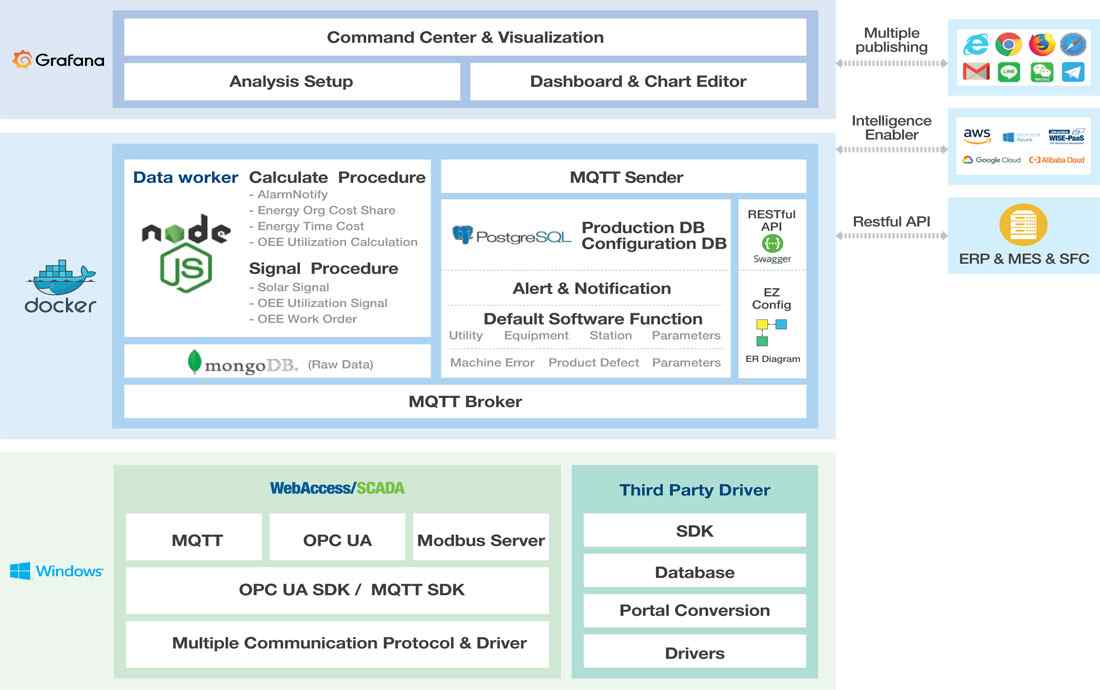

Software Diagram

System Architecture

Accelerate Your Digital Transformation with OEE Solution

Avoiding outages and minimizing downtime and interruptions to production is critical for implementing OEE projects in factories.

- Cost-effective implementation

- OEE solution can be fast deployed with little set-up time, configured with other iFactory solutions and integrated with 3rd party software and database.

- Easy maintenance and upgrades

- The configuration template provides intuitive management dashboard, and allows future upgrades and maintenance with new functionalities.

Shortening development time and reducing project cost in deploying OEE application is a win-win situation.

- Easy customization and expansion

- With industry-standard interfaces, easy configuration tools, and expandable software platform, OEE solution enables customizable KPI dashboards and incremental applications.

- Future ready

- With rapid project implementation, more IT resources can be invested to provide further value-added services for business transformation.

Visualization

Machine status can be monitored as machine running, error, idle, and machine stopped. Integrated with MES, the work-in-process (WIP) information can be connected to machine status for analyzing and improving overall production efficiency.

The runtime of each machine can be counted to calculate machine availability that reflects the percentage of planned production time the machine is available for operation. Machine availability can be utilized to evaluate the return on investment (ROI).

The comparative production analysis of day and night shifts can be examined in detail on a daily basis, to further evaluate and improve the performance.

The average change over time can be calculated to analyze daily efficiency. To figure out the small differences, accurate scheduling changeovers at the right time can improve operational efficiency.

With OEE IoT Kit that combines hardware (sensor, I/O module, edge server) and software (WebAccess/SCADA, Grafana) into integrated industrial applications, manufacturers can adopt a step-wise approach to realizing their intelligent factory.

Cost-effective implementation

- The OEE solution can deploy fast with little set-up time, and can be integrated with 3rd party devices and machines.

Easy customization and expansion

- With industry-standard interfaces, easy configuration tools, and expandable software platform, OEE solution enables customizable dashboards and incremental applications.

Data visualization

- A comprehensive data and information enable managers to gain significant intelligence and actionable insights for optimizing operation efficiency.