IIoT LoRaWAN Wireless I/O Module and Gateway Solution

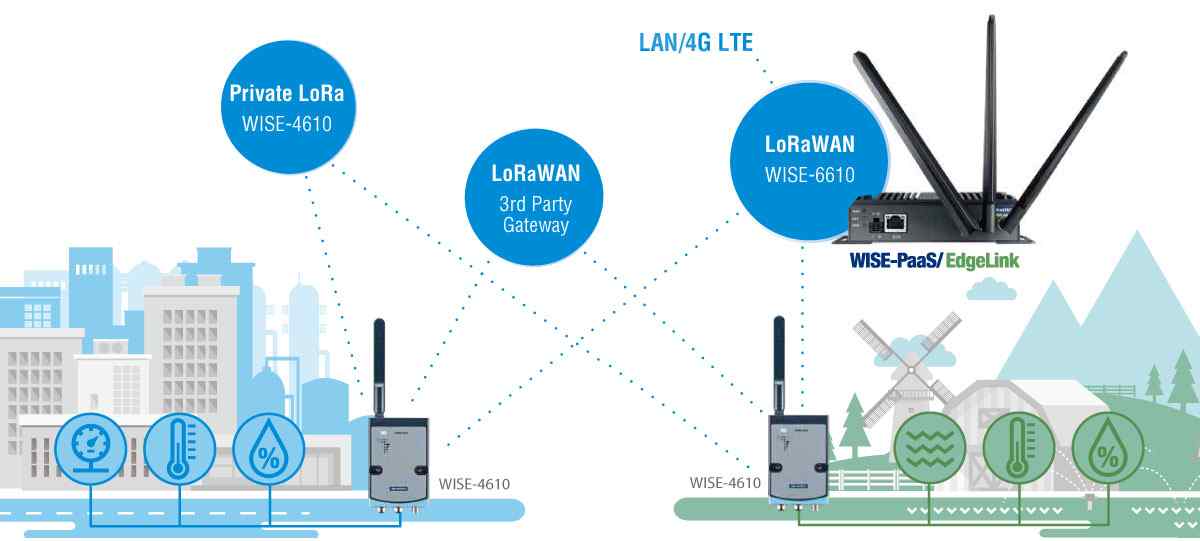

LoRaWAN provides a device-to-cloud solution by simply sending collected data through the LoRa gateway to the cloud. It supports both public LoRaWAN and private LoRaWAN solutions. With Edgelink inside the gateway, it also helps users simply plug-and-play without worrying about data parsing process.

LoRaWAN solution which is comprised of LoRaWAN I/O modules WISE-4000 series, gateways WISE-6610 series, and sensors WISE-2000 allows businesses to easily deploy a secure LoRaWAN network that can be applied to different vertical markets for industrial facility monitoring. It offers an alternative to traditional one-by-one inspections to monitor equipment and facilities, which can improve business resiliency and efficiencies.

In global community networks, routing data between devices and application servers, and connecting things to cloud enables big data analysis. AD-WISE-6610 plays a key role in connecting sensor devices to the cloud. With network service providers like “The Things Network” or WISE-PaaS EdgeLink, AD-WISE-6610 utilizes data collection to perform intelligent Internet of Things applications.

The superior features of LoRaWAN solution include:

LoRaWAN devices update data every 30 minutes and run on batteries for 2-3 years

Long range communication between devices and gateways up to 15 km (L.O.S)

LoRaWAN devices are industrial grade which can be used in harsh environments

LoRaWAN gateway configured with LoRaWAN Network Server (LNS) supports Modbus and MQTT protocols

LoRaWAN gateway can flexibly connect up to 500 LoRaWAN devices using RouterApp and Node-red

LoRaWAN devices with built-in site survey tool can correct wireless network signals

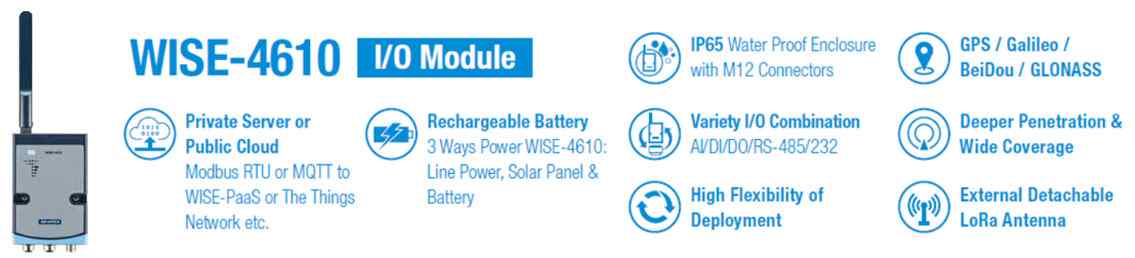

To provide a complete solution, AD-WISE-4610 features an IP65 enclosure with M12 connectors, solar panel rechargeable battery, and low-power consumption to make it as one of the best applications for outdoor deployment scenarios like smart agriculture and cities.

AD-WISE-4610 is independent; users do not have to worry about the signal coverage of base stations once the gateway deployed. Not only can users build either private networks or public networks, but they also enjoy the high flexibility of infrastructure deployment. The most important feature if that WISE-4610 offers a variety of I/O combinations. We provide device solutions with a wireless interface and added I/O to collect data from monitoring to the servers. With modularization features, you can customize WISE-4610 to any kind of I/O combination for an array of IIOT scenarios.

LoRaWAN solutions

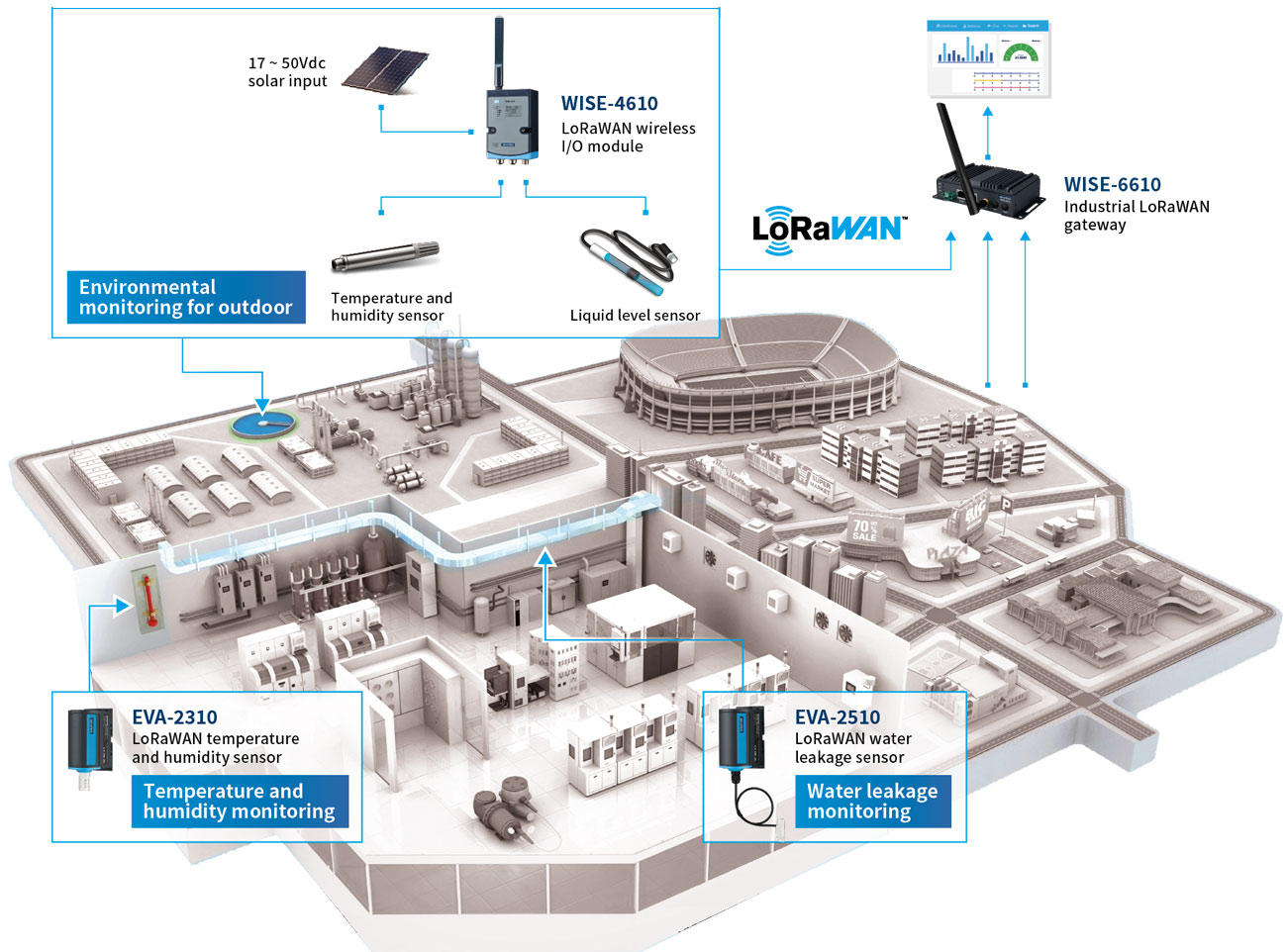

Environmental Monitoring Solution

LoRaWAN smart sensors EVA-2000 series and LoRaWAN I/O modules WISE-4610 together with LoRaWAN gateways WISE-6610 create an effective environmental monitoring solution to optimize factory operation.

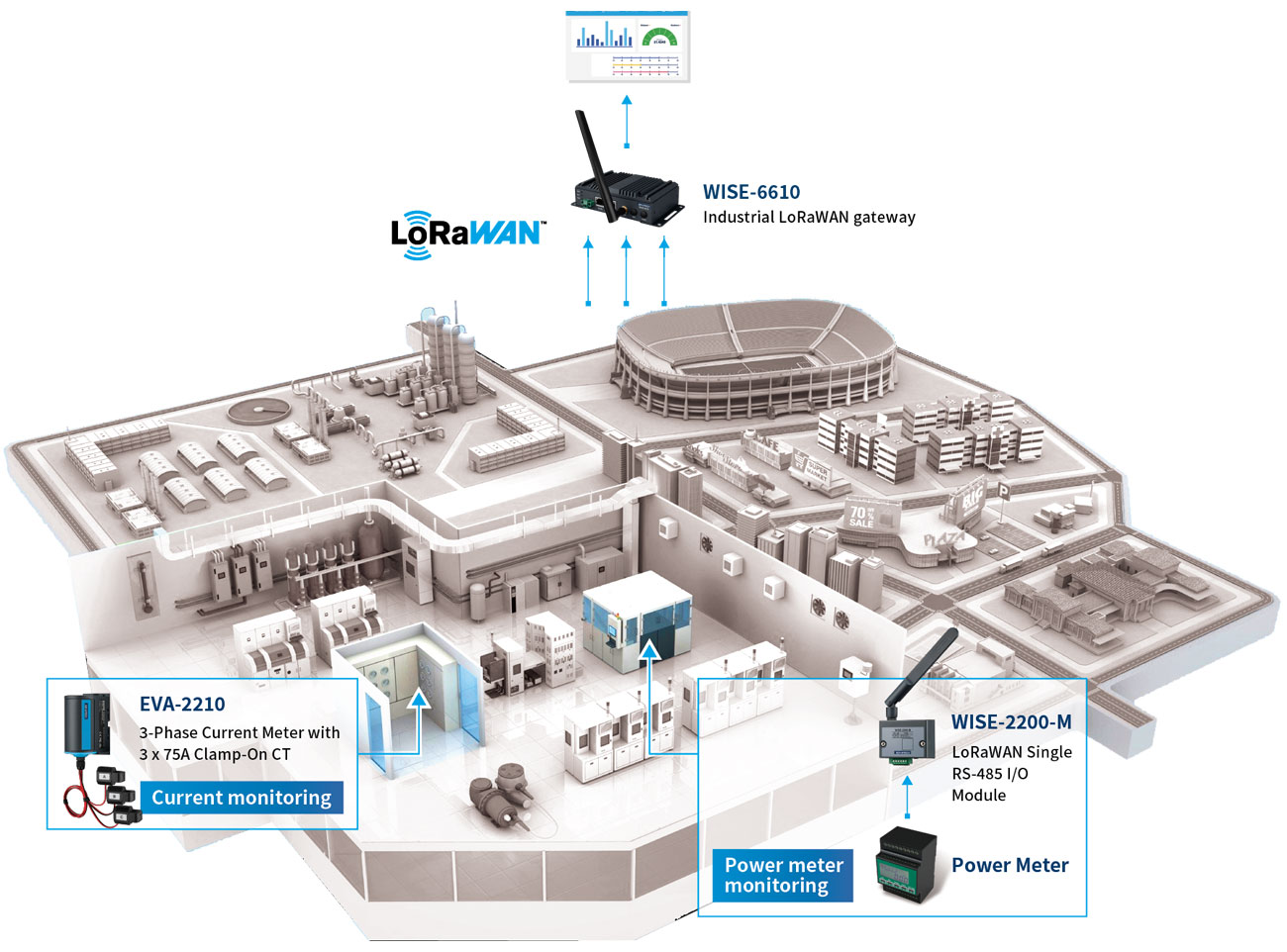

Energy Monitoring Solution

Enhance the performance of electrical equipment and energy systems in industrial factories through the implementation of a energy monitoring system. By accurately measuring electrical currents, you gain valuable insights into the operational status of essential facilities like fans and pumps. Additionally, track load trends efficiently, allowing you to make informed decisions for a more resource-conscious and energy-efficient environment.

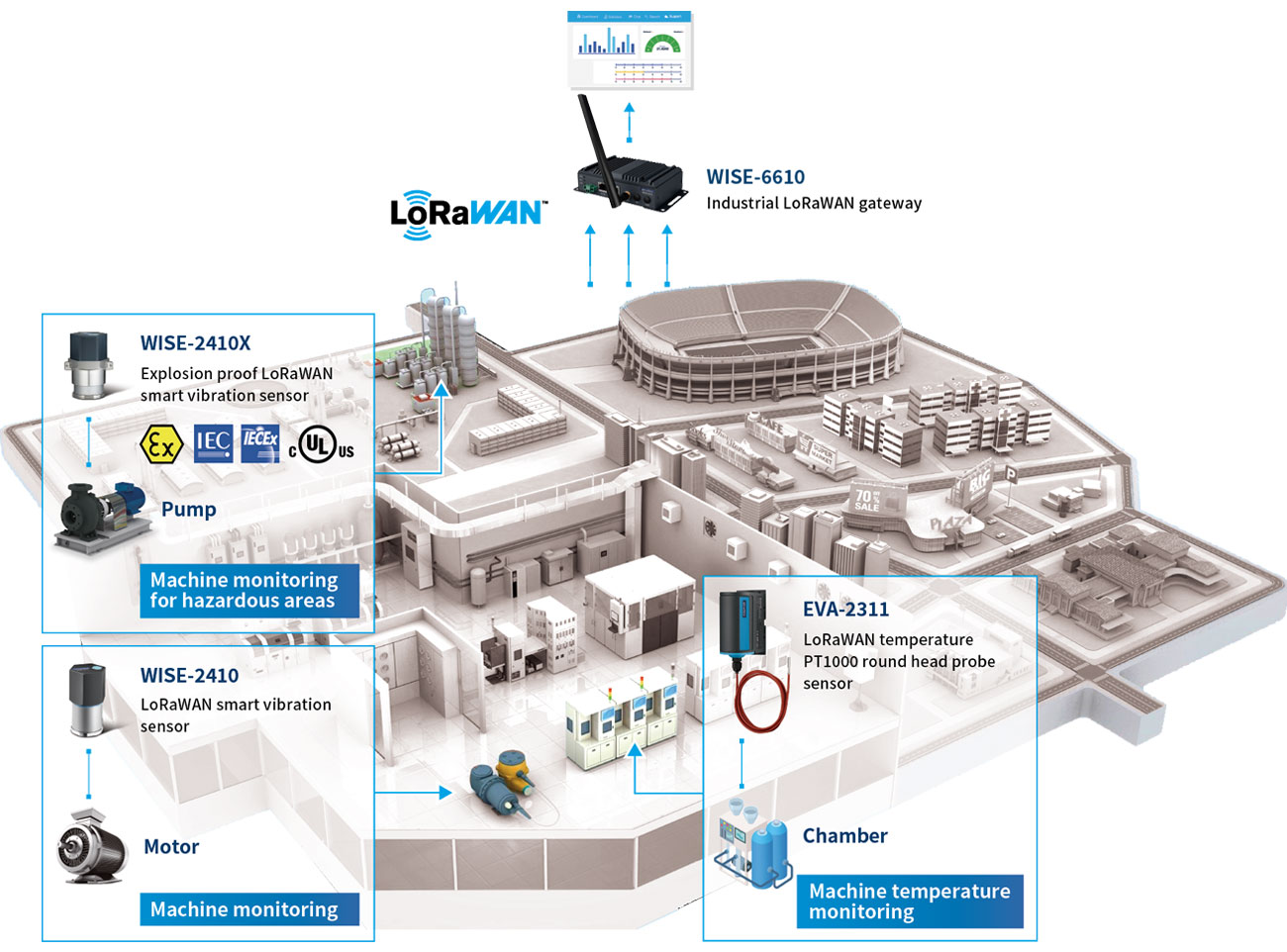

Predictive Maintenance Solution

Vibration sensor and PT1000 temperature sensor both play key roles in predictive maintenance as it can monitor machine health and detect problems before unplanned down times occur. By utilizing LoRaWAN, this turnkey predictive maintenance solution provides long-range bidirectional communication between sensors and gateways.

Scalable & Interoperable LoRaWAN Architecture

A typical LoRaWAN network is deployed in a star-of-stars topology. This provides a highly flexible communication network by supporting multiple transmission paths between end devices and gateways. The gateways forward the data to a Network Server which manage the network and transmit data to the application servers.

Factory Industrial IoT

In Factory Industrial IoT, the core objective is deploying diverse sensors to gather extensive data for analysis at a control center. Users set system thresholds and receive timely alerts for safety and productivity.

The WISE-4610 LoRa/LoRaWAN I/O node, along with WISE-2410 vibration sensors, ensures strong signal penetration without complex wiring. Integrating the EVA-2311 LoRaWAN Temperature PT1000 Round Head Probe Sensor enhances this network. Together, they monitor warehouses using vibration, humidity, and temperature sensors, providing an efficient alternative to manual inspections.

With WISE-2410 vibration sensor, EVA-2000 PT1000 sensor, and other sensors paired with a WISE-4610 analog input I/O board, alerts can be triggered when pressure levels (water pressure, oil pressure, gas pressures etc.) are abnormal. This increases safety and improves production quality by controlling resources in the manufacturing process.

Smart Agriculture

LoRaWAN solution used in smart agriculture connects WISE-2410 vibration sensor, EVA-2310 temperature and humidity sensor, and other sensors with the WISE-4610 outdoor LoRa/LoRaWAN I/O node. Together they send data through a WISE-610 LoRaWAN gateway to the cloud. In this case, the application collects temperature, humidity, vibration and soil PH data to better understand the environmental situation.

WISE-4610 is designed with an IP65 enclosure and M12 connectors to offer an optimal fit for outdoor applications. WISE-2410 is a LoRaWAN wireless vibration sensor integrated with ARM Cortex-M4 Processor, LoRa transceiver, 3-axis accelerometer and temperature sensor. EVA-2310 comes with a temperature detection range of 20 °C to 55 °C and a humidity detection range of 0%RH to 100%RH.

The WISE-6610 is a high-performance LoRaWAN gateway with reliable connectivity options for industrial environments and LoRaWAN protocol support for building LoRaWAN private and public networks.

Oil & Gas

Oil refineries are very large industrial complexes that involve many different processing units and auxiliary facilities. These facilities are dispersed over a vast industrial complex, and some of them are in hazardous environments or nearly inaccessible locations, making maintenance extremely difficult.

The WISE-2410X, an ATEX2 and IECEx (Zone 2 and Zone 21) certified vibration and temperature sensor, can be installed in hazardous environments to monitor the conditions of rotating equipment like fans and pumps. By integrating with Actility’s ThingPark Enterprise IoT platform and AWS IoT SiteWise,

LoRaWAN vibration sensing device can automatically and remotely monitor systems, making them a perfect facility monitoring solution for refining systems.

Energy Management

LoRaWAN solution enables smart campus energy management, which collects energy data and monitors power consumption in real-time. The LoRaWAN technology not only provides long-range wireless communication but also provides deep indoor coverage to easily cover multi-floor buildings.

Advantech builds the LoRaWAN network with its EVA-2210 3-phase current meter with 3 x 75A clamp-on CT, WISE-2200-M I/O modules and WISE-6610 LoRaWAN gateways to transmit the data from power meters to the cloud. EVA-2210 measures diverse equipment currents like pumps, compressors,

and more. WISE-2200-M is a LoRaWAN Modbus read/write communication device, which supports a maximum 128 addresses and a 30 rule setting and can easily connect to Modbus sensors and meters for different kinds of applications. Because of its plug-and-play functionality, EVA-2210 and WISE-2200-M can be quickly and flexibly installed to facilitate network construction.

Resources:

Wireless IoT Sensing Solutions

Modularized and Ready-to-Use Solutions High Adaptability for IoT Sensing