Delivery Robot

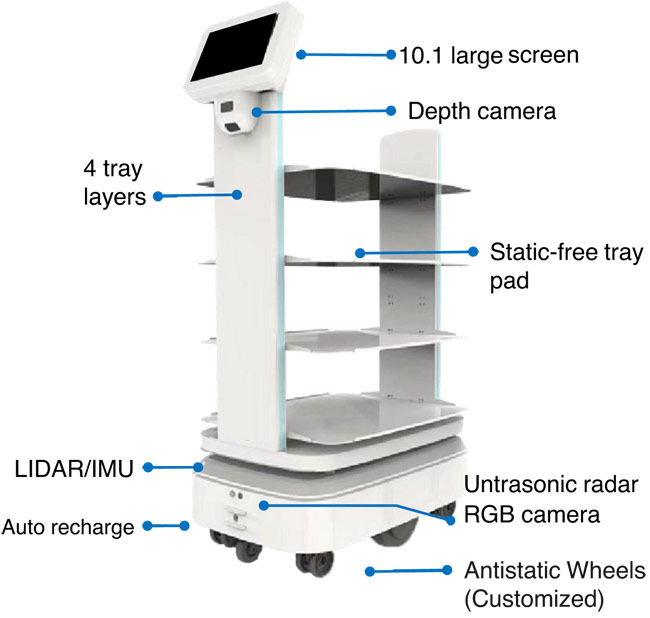

Delivery robot is designed with extended chassis to supports higher load capacity, suitable for factory, airport, etc. Adjustable trays make the robot body more flexible and configurable to support multi-point dispatch.

- 10.1" Touch screen, HD image quality display

- No marker needed for navigation

- Outstanding environmental suitability and obstacle avoidance

- Support autonomous IoT connection, elevator, electric gate, electric door, etc.

Precise positioning, flexible route planning

Flexible and accurate obstacle avoidance, crowd avoidance

precise navigation & stable movement

LiDAR-based SLAM rapid mapping and deployment

3D autonomous positioning

Factory Delivery Robot

| Dimension | 50*74*124cm |

| Tray Size | 50*62 (cm) |

| Battery | 30Ah |

| Charging time | 5h |

| Operation time | Continuous operation>10h |

| Network | 4G/wifi |

| Positioning accuracy | cm level |

| Obstacle | 20mm |

| Max load | 150kg |

| Velocity | 0.1~1.5m/s |

| Slope | ≤ 8° |

| Min passing space | 75cm |

With heavy load capability and free combination of containers, the delivery robot can satisfy all your imagination.

Standard model for light item handling, agile movement, intelligent operation in narrow spaces such as production lines, reducing ineffective personnel movement and improving efficiency. Extended chassis with a load capacity of up to 300kg, supporting flexible customization and replacement of carriers.

Flexible Customization and Expansion

Maximum Load Capacity: 80kg

Dimension: 570×500×1240mm

Maximum Load Capacity: 150kg

Dimension:740×500×1240mm

Maximum Load Capacity: 300kg

Dimension: 740×500×1240mm

Maximum Load Capacity: 300kg

Dimension: 900×600×1240mm

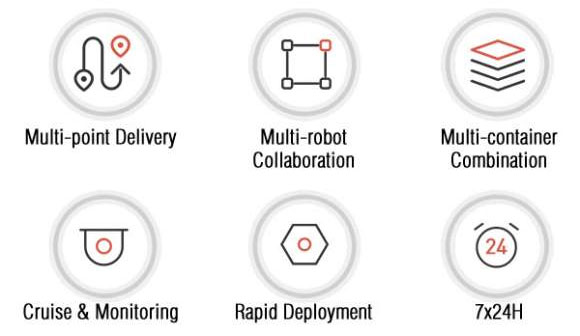

Multiple Operation Modes, Simple Interaction

Robot Call Pager

Remote call robot and multi-point delivery

IoT Devices Integration

Seamless navigation through elevator, gate and automatic door handling

Multiple Delivery Mode

A 10.1-inch operation screen for multiple delivery mode and setting

Factory Delivery Robot Applications

Delivery robots with extended chassis and higher load capacity are tailored for demanding industrial environments where the efficient transportation of heavy or bulky items is crucial. Their design emphasizes safety, autonomy, customization, and adaptability to ensure they meet the needs of diverse industries like manufacturing, logistics, and warehouse.

Features that Define Excellence:

Extended Chassis for Higher Load Capacity:

The extended chassis of the robot indicates that it has been designed to carry heavier loads compared to standard delivery robots. This feature is particularly useful in environments like factories and airports where items to be transported can vary widely in size and weight.

Suitability for Factory and Airport Environments:

Factory and airport environments often have a high demand for efficient and reliable material and goods transportation. The design of delivery robot makes it well-suited for these demanding environments where the robot can assist in moving items within large facilities.

Adjustable Trays for Flexibility:

The presence of adjustable trays on the robot offers flexibility in how items are loaded and transported. This adaptability allows the robot to carry a wide range of items, from small components to larger objects, making it a versatile solution for diverse transportation needs.

Multi-Point Dispatch Support:

The robot can be programmed to make deliveries or pickups at multiple locations within a single trip, optimizing its efficiency and reducing the need for manual intervention.

Reduced Manual Labor:

The extended load capacity and flexibility of the robot's design can significantly reduce the need for manual labor in transporting items within factories, airports, and other similar settings. This can lead to cost savings and improved worker safety.

Safety Considerations:

Safety Considerations: In environments with human workers and other equipment, safety features such as obstacle detection, emergency stop buttons, and clear visual indicators are essential to prevent accidents and ensure smooth operations.

Factory Delivery Robot Video

Integrating All-in-One Indoor Air Quality (IAQ) Sensor with Delivery Robot

Integrating IAQ sensor with delivery robots involves combining two technologies to address both air quality monitoring and autonomous delivery. The IAQ sensor is attached to the delivery robot, continuously monitoring the air quality in different locations as the robot moves through indoor environments. As the robot navigates through different areas, it collects real-time IAQ data and transmit this information to a central monitoring system.

Combining IAQ monitoring with delivery robots offers a dual-purpose solution, addressing both air quality concerns and the need for delivery systems. It enhances the value of robotic systems by providing additional functionalities beyond just delivery and also help ensure that indoor environments meet certain air quality standards.